Isometric Micro Molding now part of Nissha Medical Technologies

Isometric Micro Molding is excited to announce that the recent acquisition by Nissha Medical Technologies

Take a look at our experts’ most popular posts.

Isometric Micro Molding is excited to announce that the recent acquisition by Nissha Medical Technologies

Isometric recently appeared in a feature article written by Michael Barbella, Managing Editor for Medical

Isometric News: OEM’s Seek Molders Offering Timely Techniques Medical Product Outsourcing (MPO) magazine recently featured

Isometric Featured Article: “Diabetes Technology Manufacturers Seemingly on a Sugar Rush” Isometric Micro Molding was

Isometric Featured in Article, “Big Prospects for Medical Device Miniaturization” Medical Device and Diagnostic Industry

Isometric CEO, Donna Bibber, Featured in MDO’s “Women in Medtech 2021” Medical Design and Outsourcing

Micro Molding the Tiniest Parts On Earth Isometric’s Donna Bibber and Brent Hahn were recently

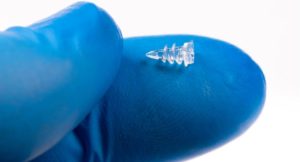

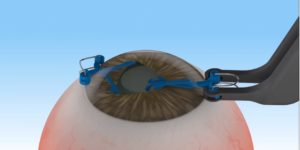

Micro Ophthalmic Ocular Implants Donna Bibber shares insight about micro ophthalmic ocular implants and the

Today’s Micro Molding Challenges, Part 2: Tooling – The Enabler Today’s Micro Molding Challenges, Part

Micro Giants: Micromolding for Medtech Medical Product Outsourcing article featuring Isometric Micro Molding, Inc. Micromolding

Micro Molding Medical Device Innovations Medical Product Outsourcing (MPO) spoke to the team at Isometric

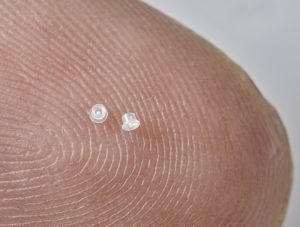

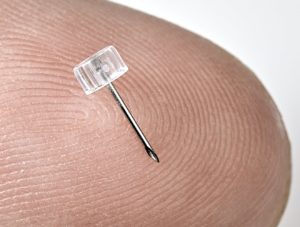

Isometric Micro Molding’s micromachining of micro molds enables thin-walled micro injection molding in thermoplastic, silicone,

Scalability of Micro-Intraocular Implants and Devices Donna Bibber discusses some of these micro-intraocular implants and

How to Approach Today’s Micro Moulding Challenges Part 1: Tooling-the Enabler Challenges in micro molding

The Four Legs That Drive MICRO Success The “four legs” that support Isometric Micro Molding

Powerful micro capabilites that bring your project to life.

Connect with our expert team of plastics engineers today!

USA PHONE +1 715-246-7005 | FAX +1 715-246-3462 | EMAIL [email protected]

240 Wisconsin Drive, New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding. All Rights Reserved.

ISO Certification 13485: 2016

USA PHONE +1 715-246-7005

FAX +1 715-246-3462

EMAIL [email protected]

240 Wisconsin Drive

New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding.

All Rights Reserved.

ISO Certification 13485: 2016

Reach out to discuss your project with one of our Micro Molding Experts.