Contact Us

Reach out to discuss your project with one of our Micro Molding Experts.

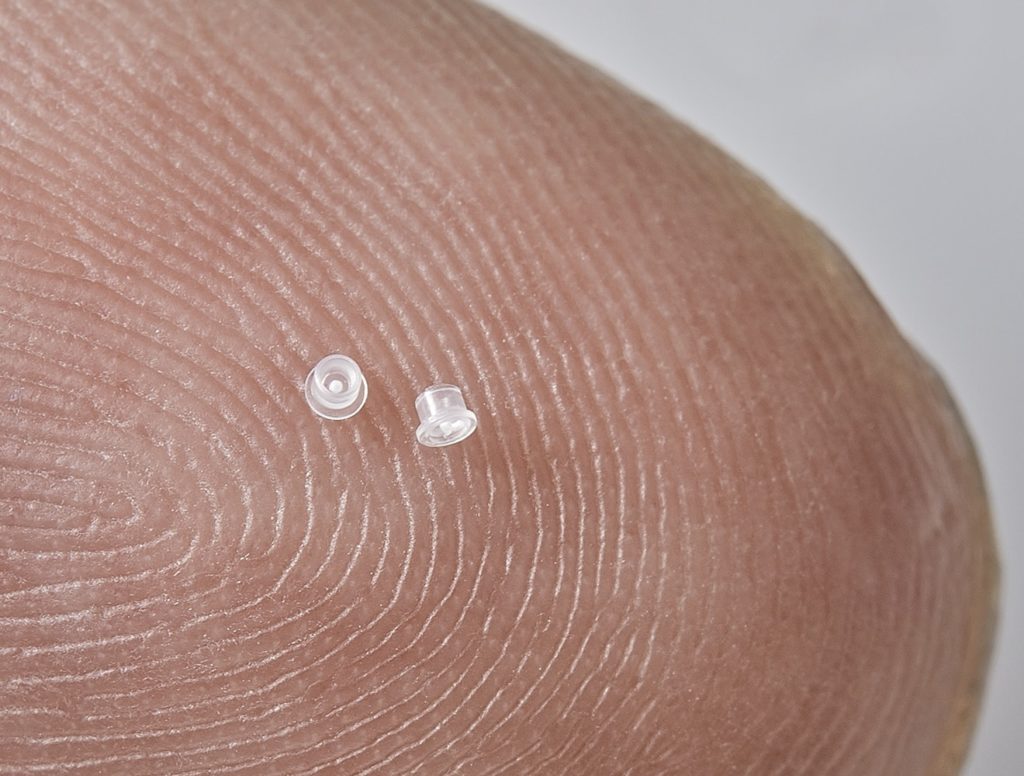

When it comes to micro molding, especially for high precision markets such as medical and drug delivery devices, it’s critical to choose a partner with industry experience. With over 30 years of experience and 1,000+ projects, Isometric Micro Molding can achieve tight micron tolerances and greater project success by tool building, molding, and assembling the complete micro solution for your project – all in-house.

Isometric can provide complete end-to-end solutions for high precision component design and micro mold manufacturing for micro to small parts (<7”) with micro features, thin walls, and/or tight tolerances.

Isometric Micro Molding’s leadership team has over 100 years of combined experience in micro injection molding. Our talented team of engineers, toolmakers, and production staff work to create comprehensive plans to reduce risks from start to finish associated with the manufacture of the most complex and precise micro molded components and assemblies.

We offer expertise at every stage of the design-to-manufacturing process. So, whether your application requires multiple materials for the most intricate over-molded component, a tiny medical implant, or a microfluidic chip with a minuscule micron tolerance, we have the materials and complex feature knowledge, experience, and understanding to achieve success.

Powerful micro capabilites that bring your project to life.

Connect with our expert team of plastics engineers today!

USA PHONE +1 715-246-7005 | FAX +1 715-246-3462 | EMAIL [email protected]

240 Wisconsin Drive, New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding. All Rights Reserved.

ISO Certification 13485: 2016

USA PHONE +1 715-246-7005

FAX +1 715-246-3462

EMAIL [email protected]

240 Wisconsin Drive

New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding.

All Rights Reserved.

ISO Certification 13485: 2016

Reach out to discuss your project with one of our Micro Molding Experts.