Contact Us

Reach out to discuss your project with one of our Micro Molding Experts.

Each phase of Isometric’s Microns Matter® PFMEA process allows for the accurate estimation of percentage micron tolerance risks, which mitigates risks during each phase. Truly, components and devices with micron tolerances can only be successfully manufactured by applying years of tooling and plastics engineering experience. These phases include:

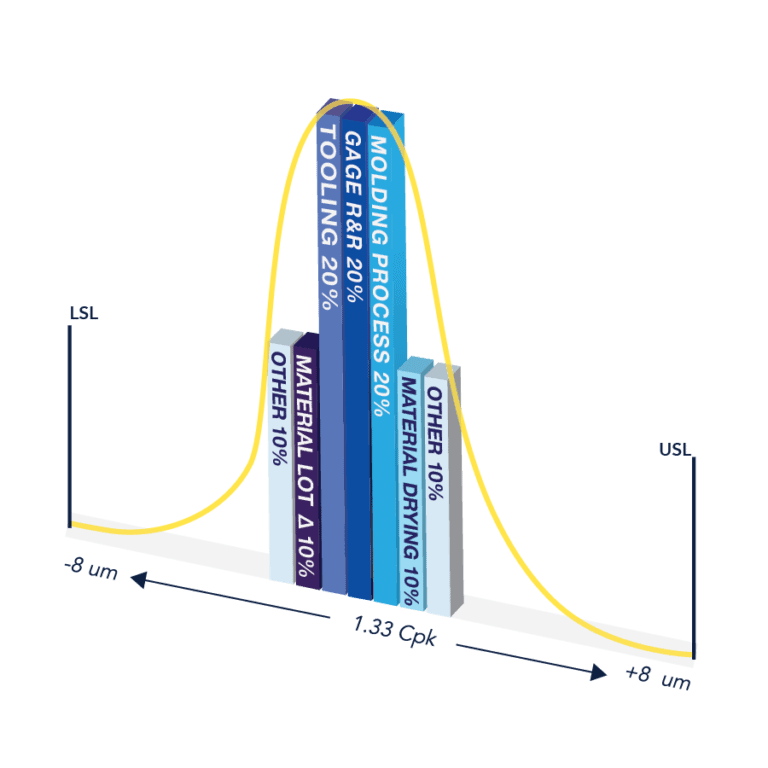

The histogram in Figure 1.1 shows the average percentage error in each of these phases for a molded part with a tolerance of +/- 8 microns (16 microns total) and a process capability index (Cpk) of 1.33.

From a risk mitigation standpoint, it’s critical to select a micro molding partner with a vertically integrated, ultra-precision mold making capability. Tooling is THE enabling technology for any micro molded component, and especially those with micron tolerances. For example, Isometric Micro Molding builds in-house micro molds to 20% of tolerance, regardless of how tight the tolerance is. 20% of tooling tolerance requires the steel to be cut to ~3 microns (~0.0001”) tolerance, and each additional micron adds 6% error to the total capability.

From our experience utilizing the Isometric’s Microns Matter PFMEA process, steel measurements are verified and recorded in the validation and design history records. Cutting steel to 20% of tolerance requires the use of EDM, milling, and wire EDM equipment that is capable of one order of magnitude beyond the total tolerance target.

By way of example, if the mold tolerance target of 20% is ~3 microns (~0.0001”), the EDM, milling, and wire EDM equipment requires accuracy of ~0.3 microns (~0.00001”) or 10 millionths of an inch. Measurement of the mold is therefore required to be 10% of that or 0.03 microns or 1 millionth of an inch.

This is where the “rubber hits the road” and is fundamental to the proven Microns Matter PFMEA process. Reviewing each step of the process — including the mold fabrication process — allows a cushion of error for the rest of the micro molding process to withstand. It is rare to have the measurement, fabrication, and environmental controls necessary to achieve these tolerances. It is for this reason that tooling is the enabling technology for the example in this white paper, a Class III micro molded device with 16-micron tolerances.

Powerful micro capabilites that bring your project to life.

Connect with our expert team of plastics engineers today!

USA PHONE +1 715-246-7005 | FAX +1 715-246-3462 | EMAIL [email protected]

240 Wisconsin Drive, New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding. All Rights Reserved.

ISO Certification 13485: 2016

USA PHONE +1 715-246-7005

FAX +1 715-246-3462

EMAIL [email protected]

240 Wisconsin Drive

New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding.

All Rights Reserved.

ISO Certification 13485: 2016

Reach out to discuss your project with one of our Micro Molding Experts.