1

years

1

+

Employees

1

+

projects

1

+

Molds Built

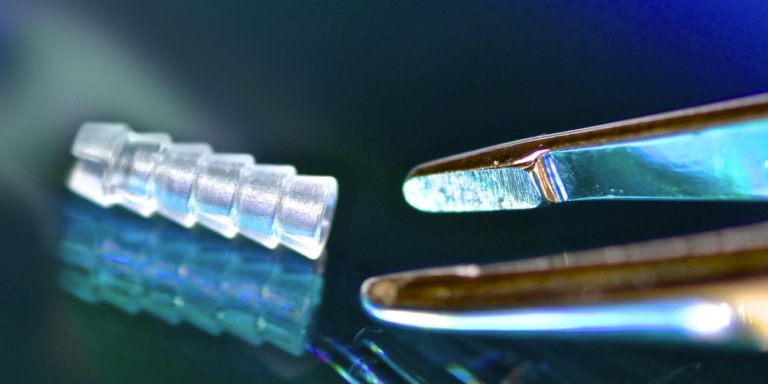

Isometric Micro Molding is able to achieve tight micron tolerances and greater project success by tool building, molding, and assembling the complete micro solution for your project all in-house–and under our control.

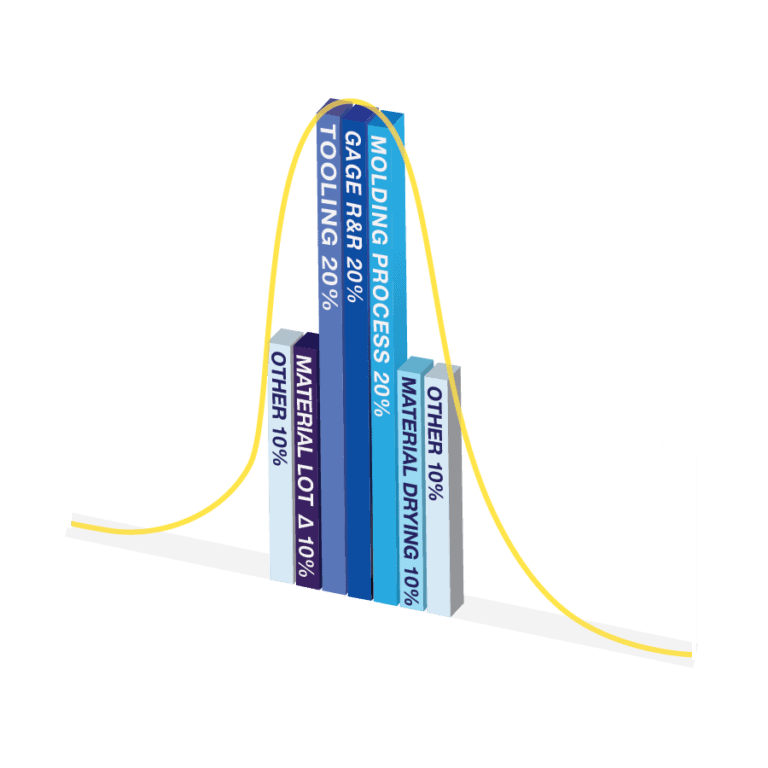

Microns Matter®– Process Failure

Mode Effects Analysis (PFMEA)

Isometric Micro Molding supports its customers from concept to volume manufacturing, which is important for the all-important topic of “design for manufacturability” (DfM).

At Isometric, DfM begins with accurate material selection for the application. It also takes into account factors such as rheological and shear strength properties, as well as environmental conditions associated with micro-level tolerances such as humidity and temperature.

DfM also considers part design, mold design, as well as mating parts, and assembly.

From the start of your project, our experts flush out any challenges that could hinder the project in production.

Through discovery and development processes, we create solutions and contingency plans that save time and money.

Accurate material selection supports the critical tolerances required for a validated and reliable product.

PRODUCT DEVELOPMENT THAT WORKS, FROM START TO FINISH

Our team adheres to strict guidelines throughout the entire micro-manufacturing process to make sure your product hits all of the design requirements at every step. Every additional analysis we perform on your design assures your product works exactly as expected.

Our experts begin each project with transparent customer collaboration to create an accurate assessment of the product and intentions for use.

From concept to design, our team creatively solves challenges based on our vast experience in tooling, molding and assembly.

The DfX (Design for Excellence) process at Isometric saves customers time, late stage project revisions, and money (in error-related issues).

The Isometric team assists all customers with DfA, to assure the product design moves forward with the correct components and sub-assemblies. By analyzing these factors, we can do more with less: production optimization and costs for assembly. In fact, this invaluable foresight, when combined with our ultra-precision capabilities, allows our customers to achieve greater success, faster.

We reduce product assembly costs by reducing yield loss and number of needed assembly operations for successful part production.

Isometric's automated assembly experts create a highly repeatable and fully inspected as well as in-line tested assembly solution that reduces bioburden.

Isometric does more in less space to create efficient and less costly solutions. The smart assembly design approach reduces labor and creates a robust solution that requires less maintenance for more "up time".

Industry 4.0 Revolution At Isometric

Welcome to the newest manufacturing revolution where smart technology pushes the automation of traditional manufacturing to the next level. By sharing the large amounts of data created by our manufacturing processes with our customers they can use advanced data analytics to design smarter parts for the future.

Markets We Serve Include:

Materials Expertise:

Micro Applications Include:

Powerful micro capabilites that bring your project to life.

Connect with our expert team of plastics engineers today!

USA PHONE +1 715-246-7005 | FAX +1 715-246-3462 | EMAIL [email protected]

240 Wisconsin Drive, New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding. All Rights Reserved.

ISO Certification 13485: 2016

USA PHONE +1 715-246-7005

FAX +1 715-246-3462

EMAIL [email protected]

240 Wisconsin Drive

New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding.

All Rights Reserved.

ISO Certification 13485: 2016

Reach out to discuss your project with one of our Micro Molding Experts.