Isometric’s Microns Matter® PFMEA Process

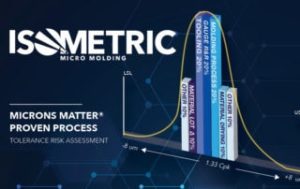

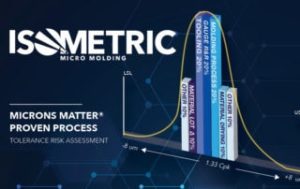

Isometric’s Microns Matter® PFMEA Process Figure 1.1 Isometric Micro Molding “Average” Tolerance Risk Assessment Strategy

Take a look at our experts’ most popular posts.

Isometric’s Microns Matter® PFMEA Process Figure 1.1 Isometric Micro Molding “Average” Tolerance Risk Assessment Strategy

Isometric’s Microns Matter® Proven Process for Medical Micro Molding Micro molding for critical applications requires

Microns Matter® 5 Steps to Micro Molding Success With over 30 years of experience in

Powerful micro capabilites that bring your project to life.

Connect with our expert team of plastics engineers today!

USA PHONE +1 715-246-7005 | FAX +1 715-246-3462 | EMAIL [email protected]

240 Wisconsin Drive, New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding. All Rights Reserved.

ISO Certification 13485: 2016

USA PHONE +1 715-246-7005

FAX +1 715-246-3462

EMAIL [email protected]

240 Wisconsin Drive

New Richmond, WI 54017, USA

Copyright © 2024 Isometric Micro Molding.

All Rights Reserved.

ISO Certification 13485: 2016

Reach out to discuss your project with one of our Micro Molding Experts.